- About

- Products

- Fabrication

- Services & Repairs

- Industries

- Manufacturers

- Resources

- Careers

- Contact

SIT Elatech develops, engineers, manufactures and distributes high quality solutions and components for power transmission and conveying for industrial applications of excellence worldwide, with the aim of increasing the productivity of its customers’ machines and systems.

Through its team of technicians and engineers dedicated to research and development and a technology centre equipped with advanced dynamic test benches and sophisticated raw material and finished product testing instruments, SIT Elatech offers very high quality products and solutions.

As a result of top-quality, state-of-the-art machinery and techniques such as water jet cutting, ELATECH® timing belts can be mechanically processed to perform special and complex tasks. The extremely precise machining and finishing operations guarantee strictest tolerance requirements and maximum reliability of ELATECH® timing belts in all the most complex and demanding industrial applications.

Benefits

Download

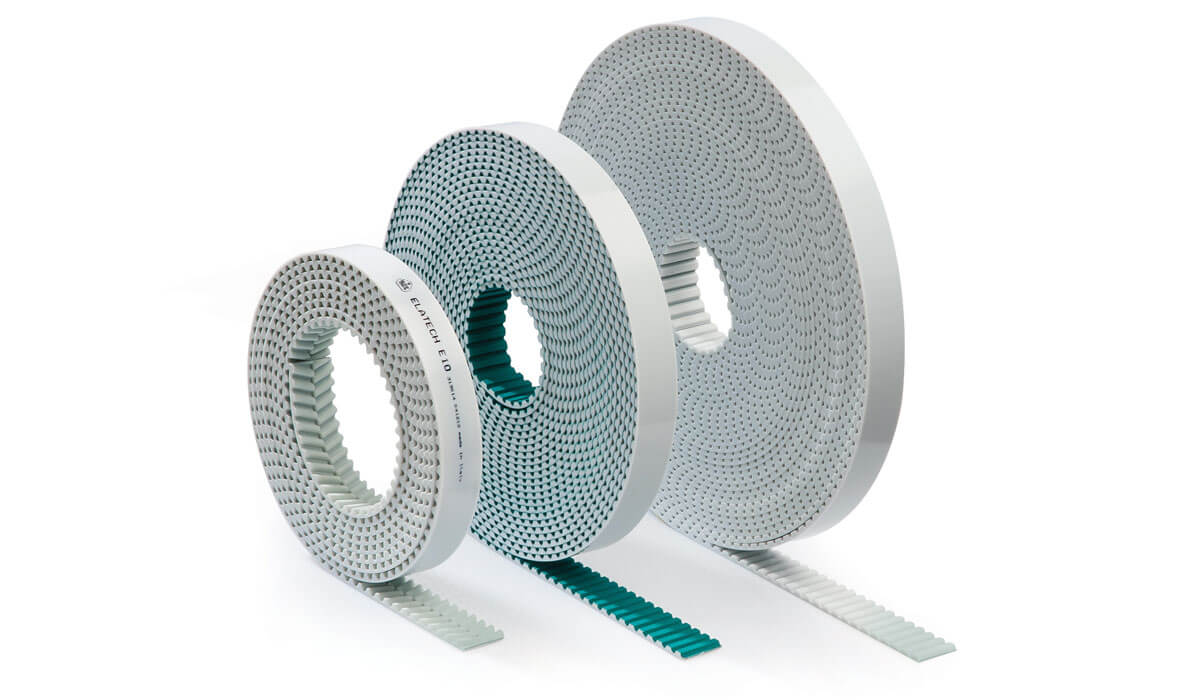

ELATECH® M open end belts are produced in standard roll length of 100 meters and delivered to any desired length. The excellent precision, dimensional stability and high abrasion resistance make them ideal in all linear motion applications.

ELATECH® V are jointed belts obtained from open-end belts. Special manufacturing process allows for obtaining any desired length. Due to high flexibility and unique precision in positioning offered, ELATECH® V belts are ideal for all conveying applications where synchronization is needed.

Available with standard pulleys in aluminum, cast iron or steel, with solid hub, for mounting SER-SIT® taper bushing or according to customer specifications.

Wide range of timing bars available on stock.

Characteristics

Pitch:

T (2,5 – 5 – 10 – 20) | AT (3 – 5 – 10 – 20) | SAT (10)

TK5-K6 – TK10-K6 – TK10-K13 (SELF CENTERING) | ATK5-K6 – ATK10-K6 – ATK10-K13 (SELF CENTERING)

MXL – XL – L – H – XH

HTD (3 – 5 – 8 – 14) | RTD (5 – 8 – 14) | STD (5 – 8 – 14)

EAGLE (5 – 8 – 10 – 14)

FLAT (1 – 2 – 2,5 – 3 – 9)

POLY-V K

T10 – AT10 – HTD8 – Total Protection | TT5

Benefits

Download

ELA-flex SD® timing belts are manufactured with truly endless high-tension strength steel tension cords and high wear, abrasion and tear resistant polyurethane. Having no splice or welding, the belts have no weak cross sections. ELA-flex SD® timing belts are therefore ideal for high speed power transmission and high load conveying applications.

Unique high-tech manufacturing process designed by our research and development permits the production of every belt length, tooth by tooth from a minimum of 800 mm to a maximum of 24.000 mm to allow for the best flexibility in application.

Available with standard pulleys in aluminum, cast iron or steel, with solid hub, for mounting SER-SIT® taper bushing or according to customer specifications.

Wide range of timing bars available on stock.

Characteristics

Pitch:

T (5 – 10 – 20) | AT (5 – 10 – 20)

MXL – XL – L – H – XH

HTD (5 – 8 – 14) | RTD (5 – 8 – 14) | STD (5 – 8 – 14)

EAGLE (8 – 10 – 14)

FLAT (2 – 2,5 – 3 – 9)

ATK10 – K6

ATM10

Benefits

Download

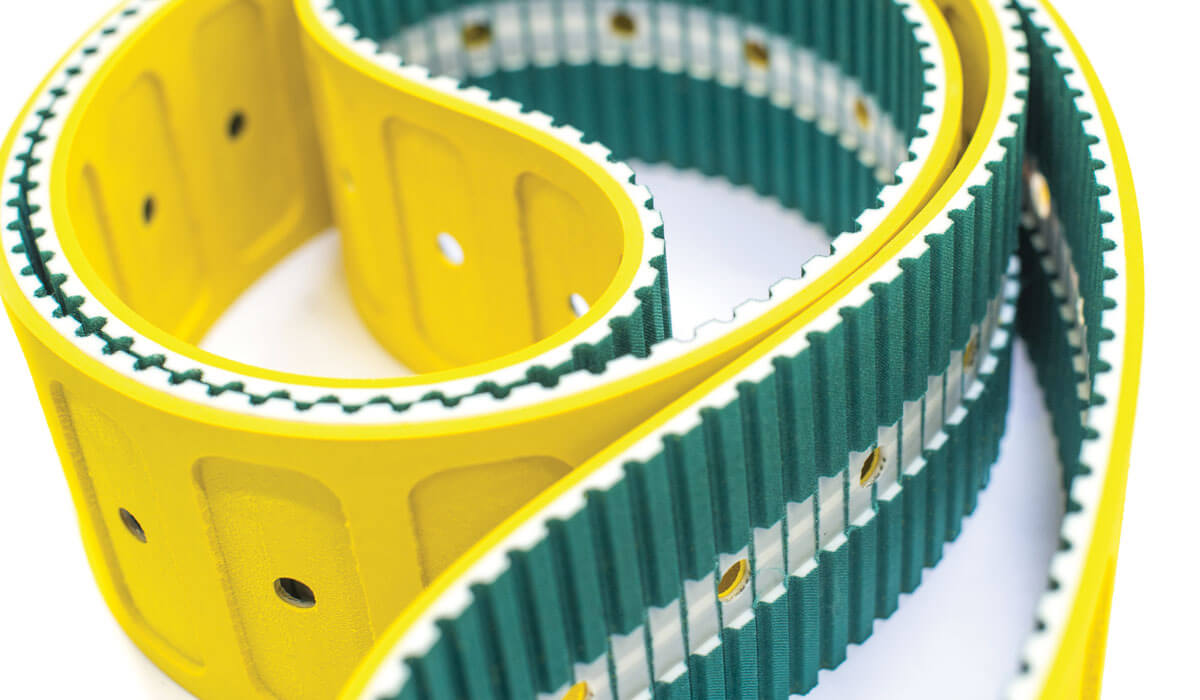

ELATECH® SYNCRO-MAX® Extra-wide Polyurethane Belts extend the advantages of synchronous timing belts to wider surfaces and to the typical applications of flat and modular conveyor belts.

Made of Polyurethane and reinforced with Aramid, ELATECH® SYNCRO-MAX® Extra-wide Belts provide positive drive and synchronous conveying resulting in no slippage, better tracking, higher indexing/positioning precision, smaller drive pulley requirements, lower belt tension, lower shaft loads and consequent power saving.

Available with standard pulleys in aluminum, cast iron or steel, with solid hub, for mounting SER-SIT® taper bushing or according to customer specifications.

Wide range of timing bars available on stock.

Characteristics

Benefits

Download

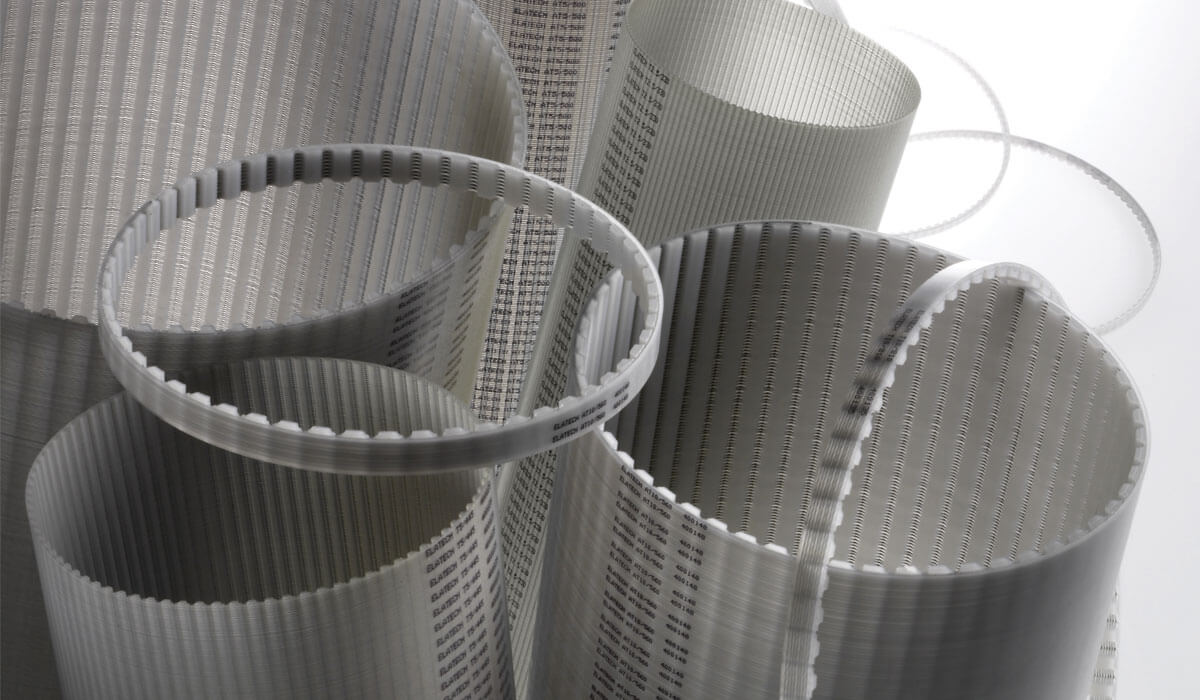

Elatech iSync® timing beltsare innovative high-performance belts for power transmission made with polyurethane resin body and tension cords in steel or Aramid fiber. The high elastic modulus of tensile cords allows a good dimensional stability under load. The production process, based on a unique and highly sophisticated technology, together with the high quality of the materials in use make Elatech iSync® belts extremely precise. Moreover, Elatech iSync® belts allow to transmit up to 30% more than the T and AT conventional belts resulting in long lasting belts or in a more compact drive.

Available with standard pulleys in aluminum, cast iron or steel, with solid hub, for mounting SER-SIT® taper bushing or according to customer specifications.

Wide range of timing bars available on stock.

Characteristics

Benefits

Download