- About

- Products

- Fabrication

- Services & Repairs

- Industries

- Manufacturers

- Resources

- Careers

- Contact

Heavyweight lace fastener options include:

Your belt’s characteristics will determine which lacing fastener should be used. Belt Power created this chart to help you select the most suitable fastener for your specific application.

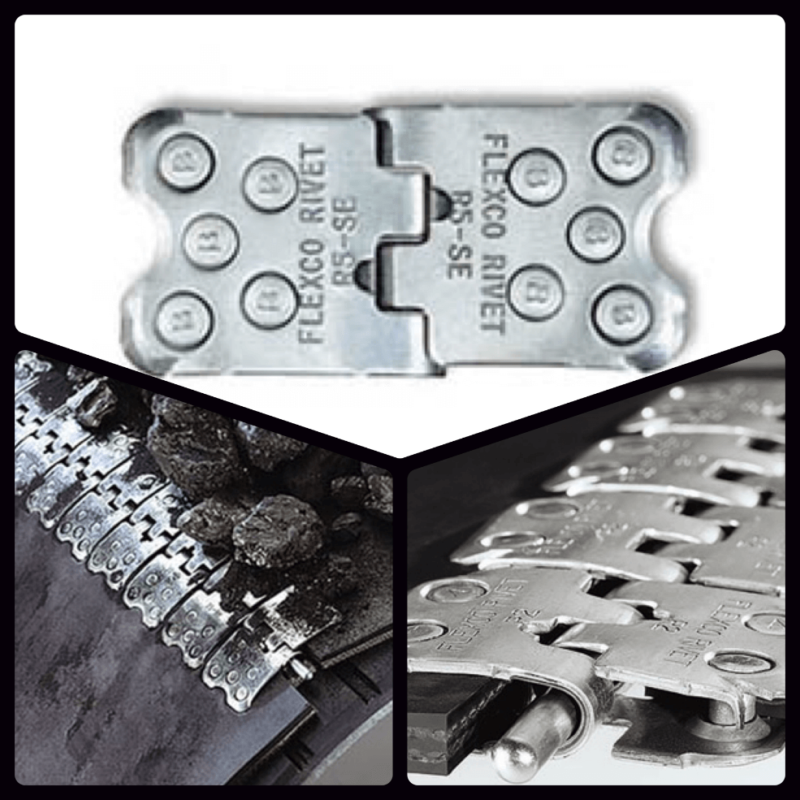

Flexco® Bolt Solid Plate fasteners are engineered to meet the demands of the toughest material handling applications, providing a strong, sift-free splice with superior holding ability. A choice of sizes accommodates belts from 3/16” (5 mm) to over 15/16” (24 mm) thick.

Market applications:

For belt conveyor applications subject to frequent length adjustments, the Bolt Hinged fastener is easy to install – and re-install. The joint can be separated simply by removing the hinge pin. On-site installation requires hand or power tools. Our exclusive piloted bolt also simplifies installation and holds fastener plates firmly in place. For added strength and pull-out resistance, specially formed teeth penetrate deep into the belt carcass without damaging carcass fibers.

Market applications:

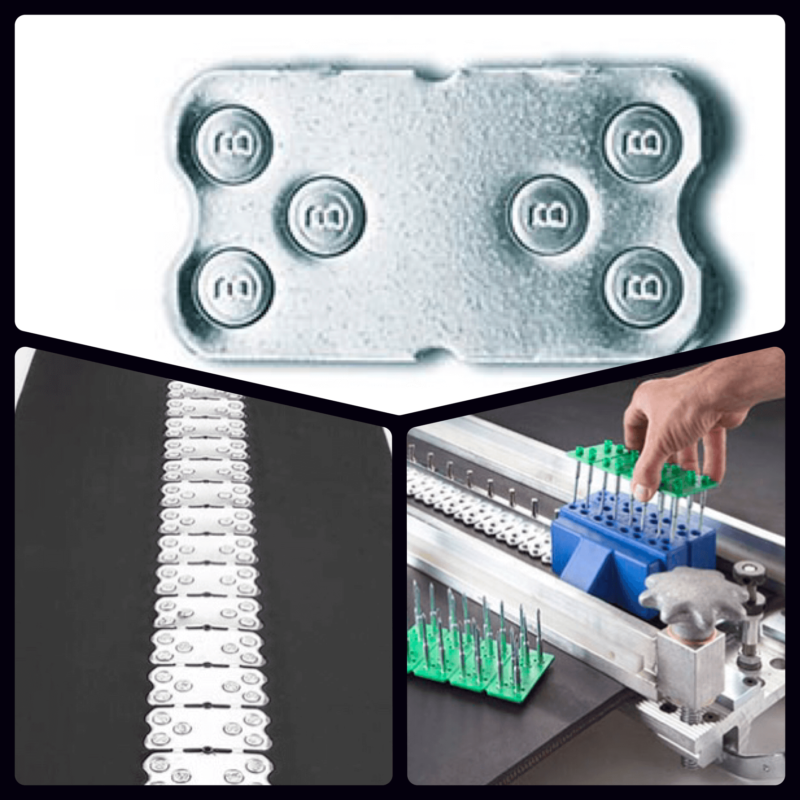

Ideal for pulley diameters as small as 14” (350 mm), the 6-rivet configuration provides a staggered, multiple-point rivet attachment to allow rivets to pass between carcass fibers without severing them for maximum resistance to pull-out. Plus the patented Scalloped Edge™ provides for a lower fastener profile to extend belt splice life and reduce exposure to belt cleaner blades and other conveyor components.

The Flexco® SR™ Rivet Hinged Fastening System has earned a reputation for quality and performance in the most demanding material handling applications on earth. Wherever belt conveyors are used, you need a fastener system that lets you set up, splice, and get out of the way … fast. Flexco SR fasteners deliver the performance, long life, and easy installation that maximize belt availability and help keep productivity on a roll.

Market applications:

The SUPER-SCREW® is a flexible rubber splice with steel inserts for joining conveyor belts as an alternative to traditional vulcanizing. It has specific screws that are self-drilling and self-tapping (they spread the carcass threads without cutting them). Not only is the SUPER-SCREW® a great way to fasten the ends of a belt but it can also be used as a patch repair if material punctures the belt.

Advantages: