- About

- Products

- Fabrication

- Services & Repairs

- Industries

- Manufacturers

- Resources

- Careers

- Contact

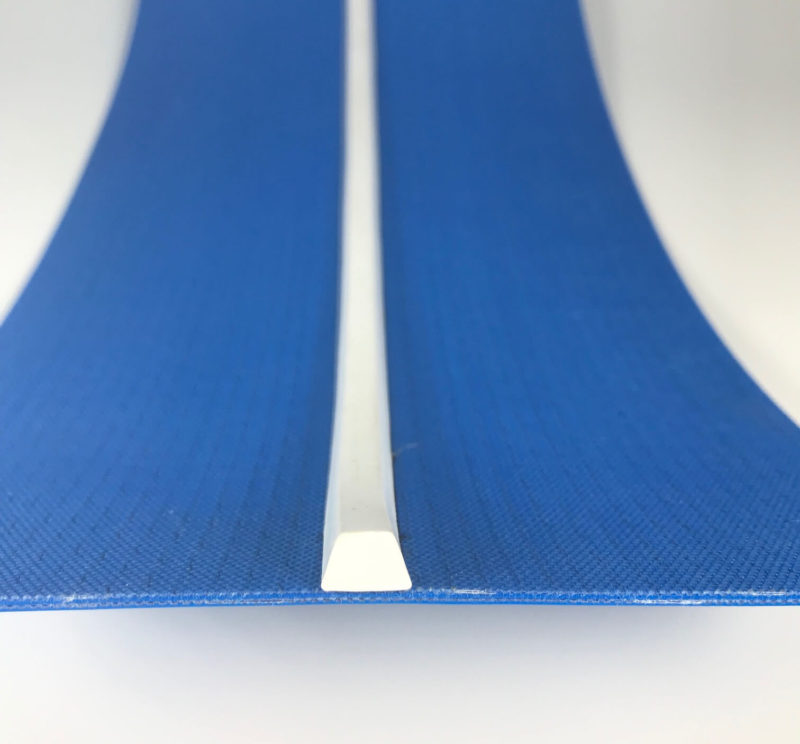

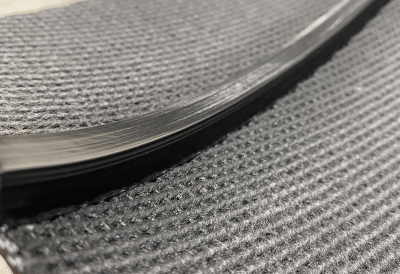

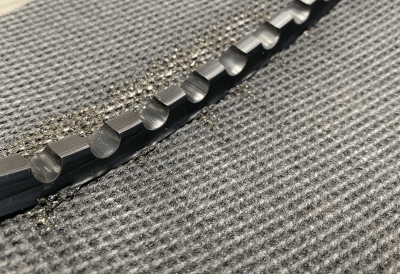

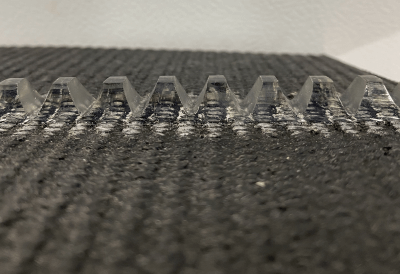

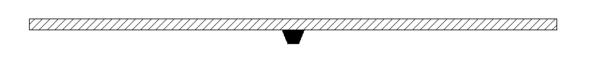

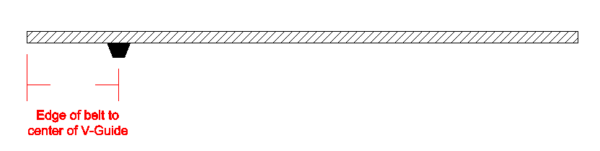

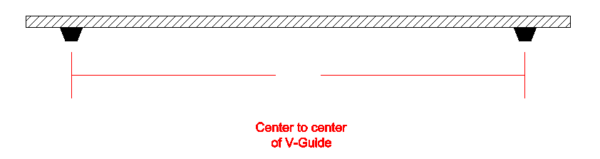

V-guide fabrications are v-shaped profiles that run along the underside or topside of the conveyor belt. Multiple v-guides can be vulcanized or welded on a single belt; size, location, and quantity vary depending on your application’s needs.

V-guide conveyor belts provide additional belt tracking support and help prevent miss-tracks. They are ideal for applications where the belt is long and narrow or wide and short, especially when the belt is prone to inconsistent load distribution along its surface area. Since v-guides improve tracking consistency, they extend the conveyor belt’s life by reducing the amount of wear on either edge. Additionally, improved tracking will reduce conveyor belt failures, improving your conveyor’s uptime and production output.

Belt Power will keep you on track with our wide variety of v-guide tracking solutions. Check out our v-guide selection today and call us at 800-886-BELT (2358) with any questions. We are here for you 24/7/365.

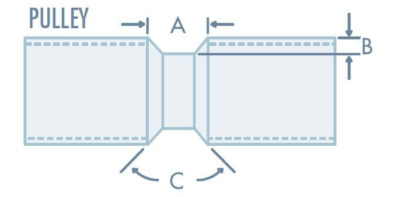

Note: All v-guide conveyor belt layouts can be applied on the pulley (bottom) side or conveying (top) side of the belt. Please specify which when requesting a quote.

Note: An exception should be considered for guiding profiles in short, but wide conveyors (100″ W x 48″ L). In this case, it’s advisable to make the grooves in the pulleys narrower than those in the slider bed.

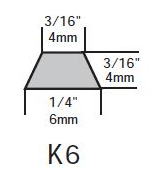

| Material | Base (width) | Height | Top (width) | Min pulley (solid) (IN) | Min pulley (notched) (IN) |

| PVC | 6mm | 4mm | 4mm | 1.5 | 1 |

| PU | 6mm | 4mm | 4mm | 1.5 | 1 |

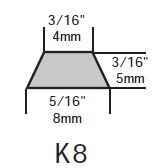

| Material | Base (width) | Height | Top (width) | Min pulley (solid) (IN) | Min pulley (notched) (IN) |

| PVC | 8mm | 5mm | 4mm | 2 | 1.5 |

| PU | 8mm | 5mm | 4mm | 2 | 1.5 |

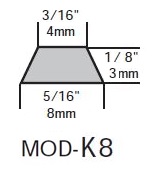

| Material | Base (width) | Height | Top (width) | Min pulley (solid) (IN) | Min pulley (notched) (IN) |

| PU | 8mm | 3mm | 4mm | 1.5 | N/A |

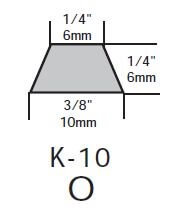

| Material | Base (width) | Height | Top (width) | Min pulley (solid) (IN) | Min pulley (notched) (IN) |

| PVC | 10mm | 6mm | 6mm | 2.5 | 2 |

| PU | 10mm | 6mm | 6mm | 2.5 | 2 |

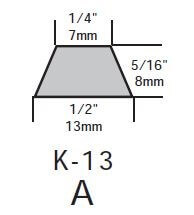

| Material | Base (width) | Height | Top (width) | Min pulley (solid) (IN) | Min pulley (notched) (IN) |

| PVC | 13mm | 8mm | 7mm | 3.5 | 3 |

| PU | 13mm | 8mm | 7mm | 3.5 | 3 |

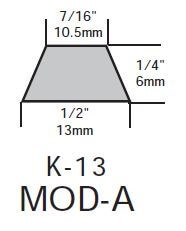

| Material | Base (width) | Height | Top (width) | Min pulley (solid) (IN) | Min pulley (notched) (IN) |

| PVC | 13mm | 6mm | 10.5mm | 3 | 2.5 |

| PU | 13mm | 6mm | 10.5mm | 3 | 2.5 |

| Material | Base (width) | Height | Top (width) | Min pulley (solid) (IN) | Min pulley (notched) (IN) |

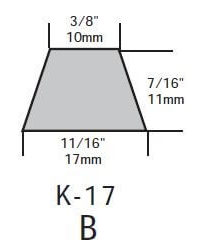

| PVC | 17mm | 11mm | 10mm | 4.5 | 4 |

| PU | 17mm | 11mm | 10mm | 4.5 | 4 |

| Material | Base (width) | Height | Top (width) | Min pulley (solid) (IN) | Min pulley (notched) (IN) |

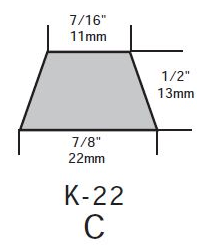

| PVC | 22mm | 13mm | 11mm | 7 | 6.5 |