- About

- Products

- Fabrication

- Services & Repairs

- Industries

- Manufacturers

- Resources

- Careers

- Contact

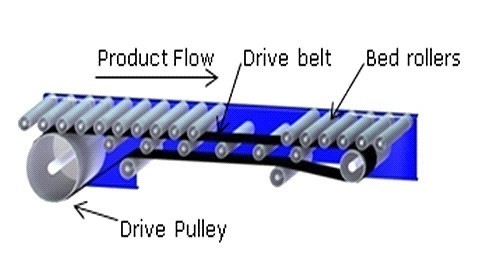

Live Roller Conveyors are used in most distribution centers and manufacturing plants around the world. Most of these systems use some kind of belting to drive the gravity rollers on a “Live Roller System”. Belt Power carries many of the live roller belting spec’s used on OEM equipment such as Dematic, Intelligrated, Hytrol, TGW and many more. Call us today if you have any live roller belting questions.

There are many ways Live Roller Systems can be powered, below are the most popular ways.

A Live Roller System is a powered roller conveyor used to move packaged and palletized goods down a line. They are commonly found in many different industries and applications, including warehousing, manufacturing, and beverage distribution. These powered rollers are a durable solution for medium-to large-size packaged product.

Live Roller Systems can be powered by v-belts, flat conveyor belts, chain, round belts or motorized pulley’s. In belted powered systems, friction between the belt and roller causes the roller to turn when the belt is driven.

Advantages

LRB2-Red is commonly found on TGW live roller systems.

LRB30-VG features a integrally molded v-guide on the bottom side for better trackability on the system.

There are many flat conveyor belts that can also be used in live roller applications. Call Belt Power to find the belt you are looking for.

For more info on Round and Flat Urethane belting Click Here

Belt Power can supply custom sprocketed rollers. For more info on sprocketed rollers Click Here

Quality punched fingers are critical to a quality endless splice. Both belt end fingers need to be evenly dimensioned with no deformation at the edge in order to mesh together for the splice, as well as for alignment in the tension direction on the conveyor.

Features and Benefits

To see a video of the finger cutter operation Click Here

When you find yourself in a downtime situation, you want the best quality splice press that completes a splice in the shortest amount of time.

Features and Benefits

To see a video of the press operation Click Here