- About

- Products

- Fabrication

- Services & Repairs

- Industries

- Manufacturers

- Resources

- Careers

- Contact

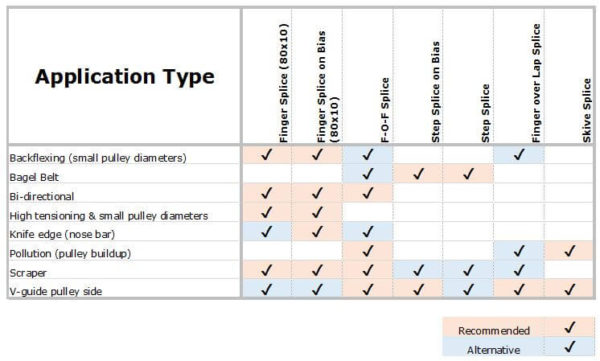

Endless conveyor belt splicing is a reliable method for conjoining belt ends to ensure maximum performance and longevity, with minimal noise. When selecting the most suitable splicing technique for your conveyor belt, it’s important to take the following factors into consideration: the belt’s construction, the strength requirements of the splice, the conveyor systems design and the specific application of your belt.

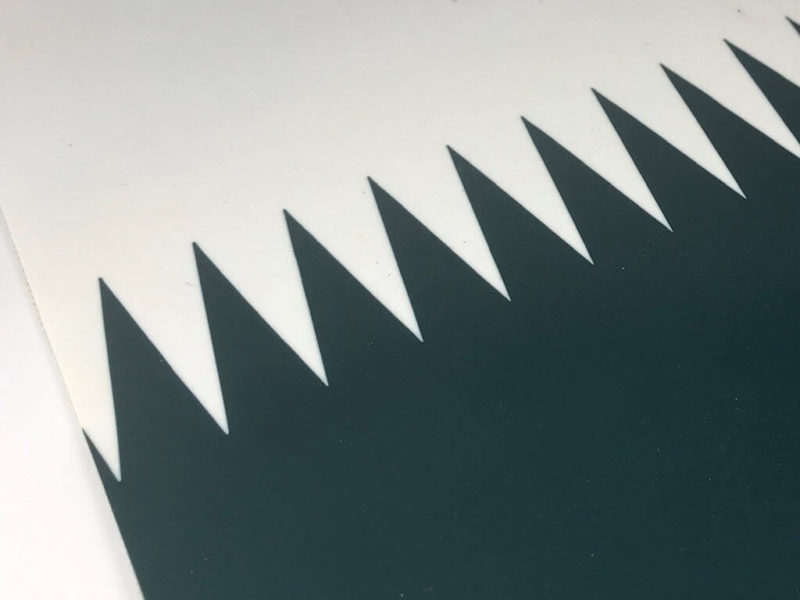

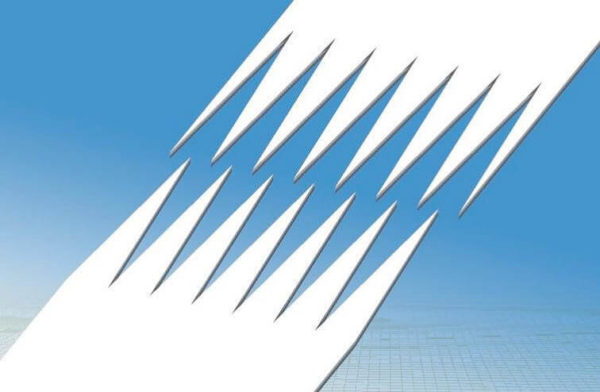

Primarily used on thermoplastic belts. These heat welded splices offer excellent flexibility and high strength. Finger splicing eliminates the need for a mechanical fastener, which reduces noise, eliminates catch points and product build-up, and allows for a clean, hygienic belt.

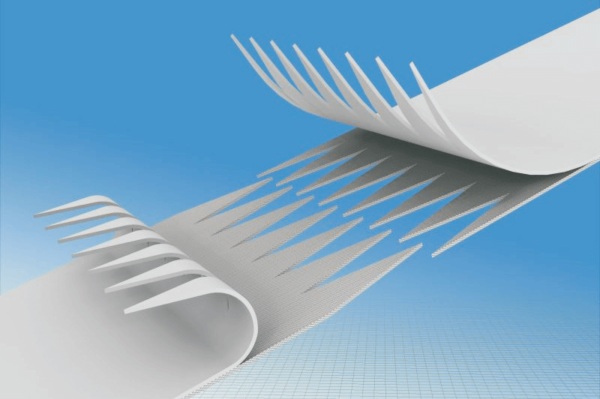

If you are having premature popping issues with your fingers on a traditional finger splice, then the finger over finger splice may be your best solution. Finger over finger conveyor belt splicing is more reliable in polluted environments, v-guided belts and inside loading circumstances. The double layer of fingers adds upward “shear” strength to the splice area.

This splice is great in troughing applications where your belt is prone to premature finger popping issues as well as situations where buildup problems are present on your pulleys. Buildup can cause upward force on the fingers, which can cause finger failure.

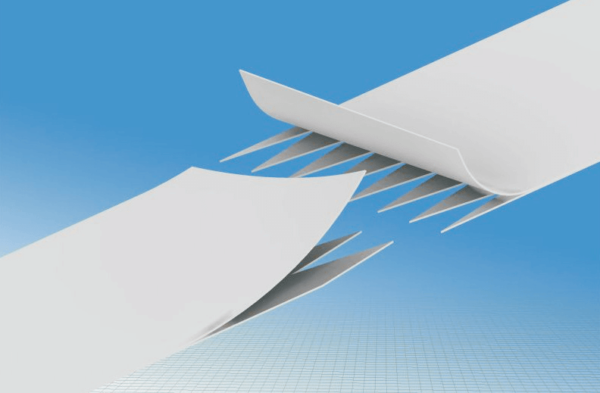

Finger on a bias is used on applications that have nose bars present. The angle allows the splice area to maneuver the nose bar at different times to avoid high friction jams, which can result in burning of the belt, gearbox, or other conveyor components.

This is a common conceyor belt splice for non-woven and nylon core belts as well as an alternate splice for thermoplastic and rubber belting. Both hot and cold glue options are available for the skive splice.

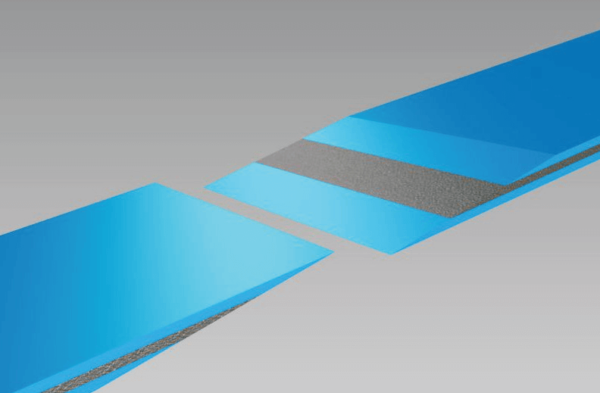

This splice retains the highest percentage of the belt strength and is used in heavier applications. It’s also a very reliable option for troughing applications. The step conveyor belt splicing method has two main techniques: Hot or cold (glued) and glued cold bond. Hot or cold glued is best utilized for thermoplastic belt styles and glued cold bond is commonly used on rubber belts.